Many factors go into selecting the appropriate Weber carburetor components: e.g., camshaft profile, ignition timing, exhaust setup, etc. Here I assume a high-lift cam and full race preparation along the lines of what some still call a Stage 3 tune. (An alternative, though still relatively aggressive, configuration using 30mm venturis is given as a reference for those who put a higher premium on "streetability," i.e., greater low-end torque and a broader power band).

Venturis

The main venturi (or choke) size depends upon factors such as the size of the engine and its peak RPM. Larger venturis result in greater, but slower, air flow, which tends to push the power band higher at the expense of low-end torque. Most Elite racers use 32mm venturis, as does EB1821.

Main Jets

Most Weberians will advise starting out with a main jet size = 4 x venturi size, which would give FWE owners a starting point of 128. The engine in EB1821 was delivered after Bill Hutton's rebuild with 138 main jets. Although these are much larger than those in any other FWE I know of, these were replaced with larger 145 main jets to correct an overly lean mixture detected just over 6000 rpm.

Air Correctors

Another rule of thumb commonly used is to choose an air corrector size by adding 50 to 60 to the size of the main jet. This is a rather crude estimate since the ratio of the main jet to the air corrector size determines the richness of the fuel/air mixture and simply adding 50 to 60 to a small main jet will have a greater effect than adding the same amount to a larger main jet. Generally speaking, increasing the main jet size increases the fuel flow across all engine speeds, while increasing the air correction jet relative to the main jet reduces the fuel flow at higher RPM. Altitude and air temperature also play their role in that thinner air at higher temperatures and altitudes may require smaller main jets to maintain the same fuel/air ratio. Had the larger main jets had a negative effect on the low rpm mixture of EB1821, we could have tried decreasing the air corrector jets, though these are already very low.

Idle Jets

Some Elite owners have complained about a flat spot when switching to Weber carbs, a problem that has apparently been annoying enough to cause some to return to the SU carbs. This probably comes as the main jets kick in and the mixture briefly becomes too lean. Since the idle jets most significantly influence this transition, I would have expected to see some experimentation here, but all the Elites for which I have data use the same 45F9 jets. The engine in EB1821 was delivered with much larger 59F21 idle jets. In spite of its very aggressive cam profile, this engine idles happily, has a very consistent fuel/air mixture across all engine speeds, and doesn't put up much of a fuss in slow moving traffic.

Emulsion Tubes

The size of the emulsion tubes depends principally on cylinder capacity and I believe they also influence the point at which the main circuit kicks in. Given that all FWEs will have a cylinder capacity in the low 300cc range, either F11 or F15 would be textbook choices, though the data I have suggests Elite owners prefer to use an F16 emulsion tube. Again, the emulsion tubes selected for EB1821 go against the grain here, but the results are clear from the dynamometer run below.

Personal Experience

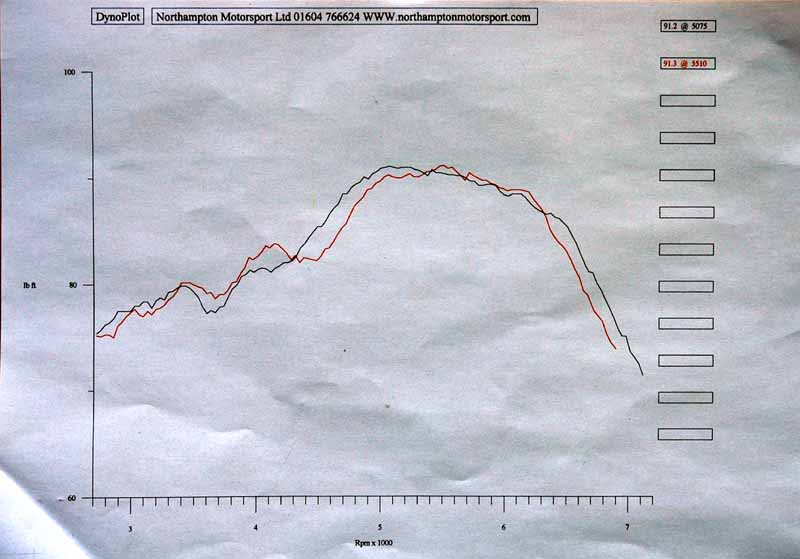

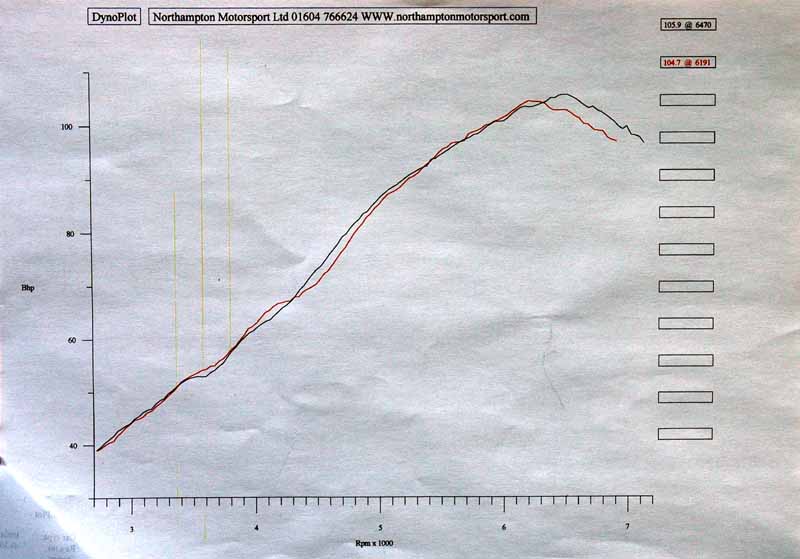

When Bill Hutton rebuilt the engine of EB1821, he selected jets that differed significantly from those reported by the Elite owners I'd surveyed. Have a look at my engine specification page to see how. In hope of getting a flatter and wider torque curve, possibly at the expense of high end power, I booked a day on a rolling road dynamometer at Northampton Motorsport. As the red lines, showing the initial power and torque curves, suggest, we already had a remarkably well tuned engine. However, analysis of the fuel/air mixture showed that it did run lean as power dropped off above 6000 rpm. We corrected this by swapping in larger main jets. The results are shown in the black lines.

EB 1821 Rolling Road Dynamometer Torque Curves

EB1821 Rolling Road Dynamometer Power Curves

When testing different jettings, be sure to reattach the jet covers. We neglected to do this at first and spent a lot of time scratching our heads over inconsistent results. I suspect the covers help to maintain consistent pressure within the carburetors.